PROJECTS

Here are some of the projects we have completed:

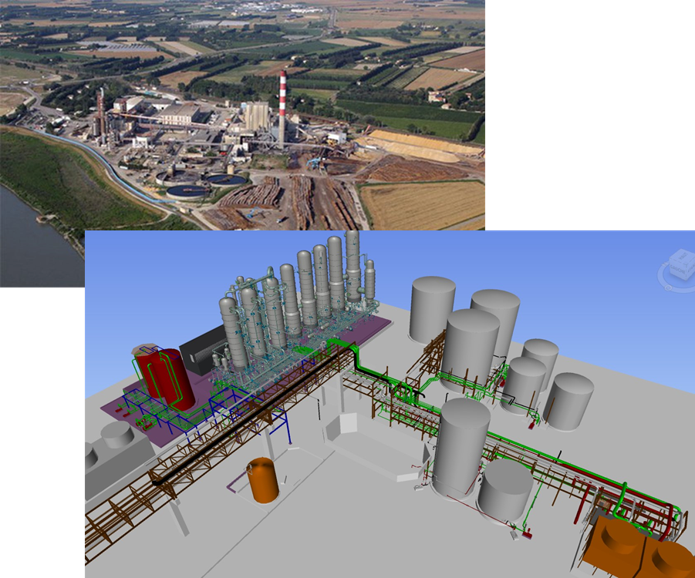

Detailed studies - Project Confidential

- Project background

During the manufacture of paper pulp, one of the residual products recovered by our customer after cooking is "Black Liquor" (LN). After treatment, this LN is used as a fuel to run the site's main steam production boiler.

The aim of the project is to replace the 2 existing lines with a single evaporation line, operating at a dryness level of 75%, in order to achieve better waste recovery.

Description of services:

IG - Integration of the evaporation unit and connection to the site.

- Piping detail studies

- 3D modelling on E3D

- Structural calculations

- Extraction of isos

Our strengths in this project

- Similar experience with a paper manufacturer

- A team with expertise in unit revamping.

- Mastery of E3D,

- Ability to absorb changes during execution

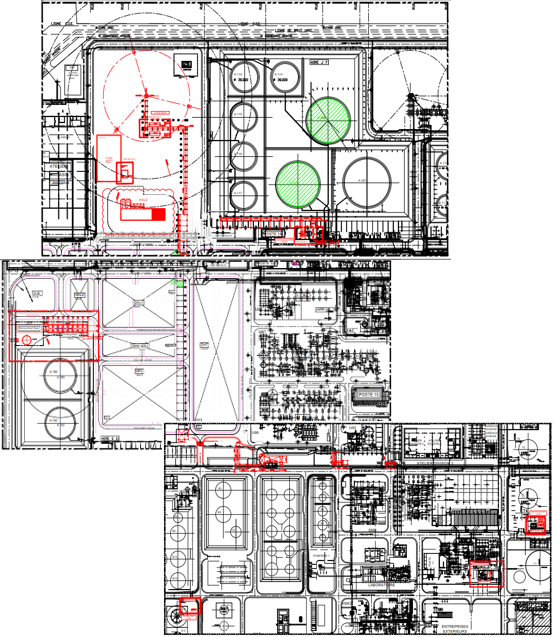

Confidential project: Piping, GC/Structure and Instrumentation studies + 3D Modelling

Project background

The customer decided to study a deep desulphurisation of its diesel, including a new hydrodesulphurisation unit in the refinery and an upgrade of the existing installations to produce Euro 5 diesel and enable the customer to move into new markets (European zone).

The new complex comprises the following units

-Diesel Hydrotreating Unit (DHT) - UOP licence

-Amine regeneration unit (ARU) - KT-KINETICS licence

-Acid water stripping unit (SWS) - Approved by KT-KINETICS

-Sulphur Recovery Unit (SRU) - Approved by KT-KINETICS

-Hydrogen Production Unit (HPU) - Licensed by TECHNIP Energies

Integration and upgrading of the NPO (utilities, flares, fire-fighting water, etc.)

Description of services

Preliminary design studies for NPOs :

- IG (Civil, structural work, pipework)

- 3D modelling on SP3D

- GC and structural studies

- EIA

Our strengths in this project

A team with expertise in unit revamping.

A team with mastery of SP3D

OTHER REFERENCES

| Year | PROJECT |

| 2022/2023 | Detail studies, 3D modelling and pipework calculations |

| 2023 | Support studies/piping plans |

| 2022/2023 | Various CAD (P&iD / PFD drawings) and TQC activities |

| 2022 | Piping and support studies (RMV Innovyn project) |

| 2023 | Planning assistance Primavera Golf 3 project |

| 2021 | flexible calculation, drafting and 3D model with isometric extraction, supports and quantity surveys for various projects |

| 2021 | Detailed design and construction of fire-fighting systems for the YAZAKI TUNISIE complex (Pomperie, sources, networks and GC) |

| 2020 | Design, basic engineering, preparation of preliminary project report and budget estimate for two strategic storage depots for white petroleum products, each with a capacity of 80,000 m3 |

| 2020 | Design, basic engineering, preparation of preliminary project report and budget estimate for a 6,000 tonne bitumen plant and 20,000 m3 diesel depot in Zarzis, Tunisia, |

| 2019 | Detailed design and construction of SVR piping -Support - EGYPT Power station project |

| 2018 | Design, installation and arrangement study, detail and construction study for two cogeneration projects (ducts, chimneys, hot/cold water circuit, etc.) SLD Tunisia and COTREL Tunisia |

| Year | PROJECT |

| 2018 | Detailed design and manufacture of SVR equipment: tanks, chimney washers and ducts |

| 2018 | Detailed design and construction of SVR piping - OTV MAROC project support |

| 2018 | Design, basic and detailed engineering for a 1,500-tonne pure bitumen depot at Jbel Ouest, Tunisia |

| 2017 | Study of various structures: - stabilisation of the three H2 vertical storage tanks with integration of guide structures - replacement of storage tanks 01V1, 01V1A and 01V5 - installation of separator tank and pilot gas circuit Furnace 01F1 |

| 2017 | Detailed design and manufacture of plastic piping and support systems for gas effluent treatment projects |

| 2017 | Detailed study and construction of a storage depot for SOJA oils |

| 2016 | Preliminary design and basic engineering, pre-sizing of 200 km white multi-product pipeline including pumping station, intermediate booster stations, sectioning stations and arrival terminal, preparation of preliminary design report |

| 2016 | Detailed study and construction of three gas distributor substations MAGNY, IZIR and BEIRE and modifications to the interconnections with pipelines for Gaz de France |

| 2016 | Detail design and construction of SVR piping -Support for cooling circuits SOUTH HELWAN POWER STATION EGYPT |

| Year | PROJECT |

| 2016 | Detailed study of requalification (modification/reinforcement of various pressurised equipment (heat exchangers, condensers, deaerators, etc.) |

| 2016 | Etude de détail et de construction pour le remplacement des deux cheminées Four 01F1 en deux variantes (acier CORTEN, Acier au carbone avec mortier réfractaire et préparation dossier d’appel d’offres |

| 2015 | Detailed design and construction of JetA1 storage tanks (3×2000 m3) BRAZAVILLE CONGO airport depot |

| 2014 | Layout, installation and pipe routing study, preparation of 3D model, detailed study and construction of JET A1 depot (2×4000 m3) PNG port MORESBY New Guinea as well as the transfer line to the airport. |

| 2014 | Detailed study of fire pump and fire network compliance DC PNR CONGO depot |

| 2014 | Detailed study to bring the fire pump and fire networks into compliance with DCI MPILA CONGO's depot requirements |

| 2013 | Detailed design and construction of SVR piping - SVR support and equipment (tanks, scrubbers, venturi, ducts, chimneys) gas washing unit fertilizer complex Morocco |

| 2013 | Design and basic engineering of a 16,000 tonnes/year lubricating oil blending unit and preparation of preliminary design and tender documents |

| 2012 | Design, installation and layout study, preparation of 3D model, basic and detailed engineering, procurement, management and supervision of construction of 10,000-tonne lubricant oil depot including brewing and manufacture of intermediate cuts for LAD ≪lubricants and various applications≫ |

| Year | PROJECT |

| 2012 | Detailed design and manufacture of SVR piping - project support ≪El Ain SOKHNA Thermal Power Plant unit 1/unit 2≫ |

| 2012 | LPG cigar requalification study, piping networks and integration of new pump |

| 2011 | Detailed study and requalification of various structures: - HP/HT steam line from boilers to turbines - Furnace inlet - outlet lines 02F103 and 02F104 - Transfer line from furnace outlet 01F1 to atmospheric distillation column 01C1 and stabilisation against vibration - Raise crude lines on R07, R08 and R09 tank sides |

| 2011 | design, installation and layout study, preparation of 3D models, basic and detailed engineering, procurement, management and supervision construction of a 5500-tonne bitumen plant and manufacture of ≪cut back≫ and emulsions in SFAX Tunisia |

| 2011 | Study of installation and pipe routing, preparation of 3D model, detailed study of pipework-Supporting Rack CX2 PIERRELATTE for a highly seismic site with significant differential settlements |